CABLE ASSEMBLIES

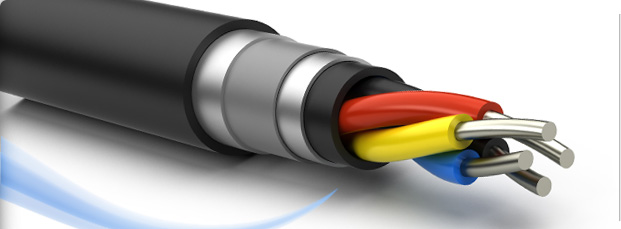

A cable assembly is only as good as its parts, and this starts with the cable itself. At Crownchris Electronic Cable, we extrude our conductors and our cable to the most exacting specifications. We offer custom cable assembly design expertise and have manufactured cable assemblies to fit a vast spectrum of flexural requirements. These abilities allow Crownchris Electronic Cable to create the custom cable assembly solutions needed in a wide range of industries.

Customizable Features

CONDUCTOR SIZES

We can extrude conductors as small as 34 gauge and as large as 12 gauge. These can be combined to create a mixed gauge cable.

- 34 awg

- 32 awg

- 30 awg

- 28 awg

- 26 awg

- 24 awg

- 22 awg

- 20 awg

- 18 awg

- 16 awg

- 14 awg

- 12 awg

CONDUCTOR COLORS

As one of the leading cable assembly manufacturers, we make cable with many conductors sometimes well over 50. To keep track of the conductors, we can use different colors. We can also mark the electric cables in other ways with stripes, dashes or even text to ensure the right conductor goes to the right spot.

AVAILABLE COLORS

- black

- white

- red

- green

- brown

- blue

- orange

- yellow

- purple

- gray

- pink

- tan

- white/black

- red/black

- green/black

- orange/black

- blue/black

- red/white

- green/white

- blue/white

- orange/red

STRANDING SIZES

Your conductors can be made with stranding as small as 0.002 inches (0.05mm) which is excellent for hi-flex, supple cables. If you just need a standard power conductor, we can use stranding as large as 0.01 inches (0.25 mm). Stranding can be bare copper, tinned stranding, tinned conductor or even plated with precious metals such as silver for increased conductivity.

SIZES

- 0.002″

- 0.003″

- 0.004″

- 0.005″

- 0.006″

- 0.007″

- 0.008″

- 0.009″

- 0.010″

- 0.013″

- 0.016″

- 0.020″

- 0.023″

CONDUCTOR INSULATION

The first protection in any cable is the conductor’s insulation. We use the range from basic PVC, PE or PP. We also use insulating materials for electric cable assemblies such as natural rubber, PU, TPE, PTFE (Teflon) and silicone.

MATERIALS

- Polyvinylchloride (PVC)

- Polyurethane (PU)

- Thermoplastic elastomer (TPE)

- Thermoplastic polyester elastomer (TPEE)

- Thermoplastic vulcanizate (TPV)

- Polytetrafluoroethylene (Teflon)

- Silicone

The hardness or softness of each material can be varied.

FILLERS

To make a cable perform its best, it is often necessary to include fillers inside electric the cable. We use materials from basic cotton to nylon to Kevlar. Each material is custom matched to the applications requirement to ensure proper performance.

- Cotton

- Nylon

- Kevlar

- PVC

- Fleece

WRAPS AND SHIELDS

Often a cable’s conductors need to be wrapped or shielded. High flex cables require a soft barrier between the conductors and outer jacket to prevent abrasion.

Many electronic cables need shielding to prevent RFI or EMI interference. We use materials such as fleece, cotton and aluminized mylar, amongst others, to create acable that will match the operating environment.

Aluminized mylar, Cotton, Fleece, Spiral wrapped stranding, Braided stranding, Polyester tie. This is typically wrapped with spiral overwrap.

JACKET MATERIALS

The final barrier between the environment and the inside of your electric cable is usually its jacket. This final covering acts as an insulator, a shield and protective cover. For your cable we can use materials as simple as PVC or as robust as natural rubber, Teflon or Silicone.

MATERIALS

- Polyvinylchloride (PVC)

- Polyurethane (PU)

- Thermoplastic elastomer (TPE)

- Thermoplastic polyester elastomer (TPEE)

- Thermoplastic vulcanizate (TPV)

- Polytetrafluoroethylene (Teflon)

- Silicone

The hardness or softness of each material can be varied.

CABLE TYPES

There are many standard cable types. The cable standards help designers choose a cable with known specifications instead of creating one from scratch. These

standards can also be used as building blocks for more complicated designs.

CABLES

- TPT

- SP-1

- SPT-1

- SP-2

- SPT-2

- SP-3

- SPT-3

- TS

- TST

- SV

- SVE

- SVEO

- SVO

- SVT

- SVTO

- SJ

- SJE

- SJEO

- SJEOW

- SJO

- SJOOW

- SJT

- SJTO

- S

- SE

- SEO

- SO

- SOOW

- ST

- STO

- STOOW

- HPN

- HSJ

- HSJO

- HS HSO

These can be made in many different gauge configurations.

UL CERTIFIED WIRE & CABLE

There are many standard UL cable types. UL standards help designers choose a cable with known specifications instead of creating one from scratch. We are certified by UL to produce many standard types of wire and cable.

WIRE

- 1007

- 1032

- 1095

- 1533

- 1571

- 1015

- 1061

- 1185

- 1569

- 2029

- 2464

- 2562

- 2725

- 2833

- 2919

- 2992

- 2096

- 2468

- 2661

- 2733

- 2835

- 2990

- 20080

- 2405

- 2560

- 2689

- 2789

- 2991

- 20276

These can be modified for color and stripping and still be UL certified.